Pallet management system

Features

The system improves logistics management significantly by individual management of pallets!

Consistent palletization is an effective method in advancing the efficiency of logistics.

However, when the collection and management of pallets is insufficient, pallet losses occur and large cost increases are conceivable.

* What is consistent palletization?

It is a transportation method of loading cargo onto one pallet and taking it to the target destination.

"A forklift can be used during transshipment," and "the time and effort of pallet reloading are saved," etc.

It is possible to increase the efficiency of transportation.

The TDS "Pallet management system" will support the enhancement of your company's logistics management.

-

RFID individual management

The system realizes individual pallet management by obtaining information on each pallet using RFID tags (tiny wireless IC chips).

-

This prevents the loss of pallets.

Attaching IC tags that allocate individual IDs enables management of when and where each and every pallet has been loaned to.

Finely detailed pallet management is provided by the TDS Information Processing Center.

* What is RFID (Radio Frequency Identification)?

RFID is a technology that uses IC tags to exchange information by wireless communication.It is possible to obtain individual information on each and every pallet by attaching IC tags to pallets.

"Pallet management system" flow

-

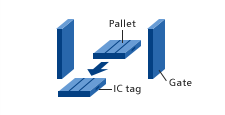

Reading in of information

Information from the IC tags attached to pallets can be read in by the pallets passing through the gate. Unlike barcodes, it is possible to read in information from multiple pallets simultaneously.

-

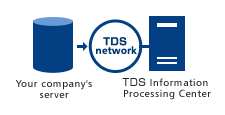

Data forwarding / accumulation

The read-in information is saved on a server. It is processed automatically and is forwarded to the database at the Information Processing Center through our network.

-

Web viewing / output

Information accumulated on the database is processed as various forms. The processed forms can be viewed or output from the customer's PC via the internet.

What are the merits of the "Pallet management system"?

The system makes the maximum use of the information obtained through the IC tags. This brings various merits.

| Merits1 | Prevention of pallet retention by customersŃĆĆPrevention of pallet loss The location of pallets can be grasped by managing pallet movement histories (shipping, collection, etc.). |

|---|---|

| Merits2 | Greater efficiency of pallet purchasing plans You can grasp the number of pallets lacking in advance by managing the total number of pallets. |

| Merits3 | Reduction of on-site workŃĆĆImprovement of work efficiency It is possible to read in information on multiple pallets simultaneously by using IC tags. |

| Merits4 | Use of individual pallet information Information accumulated in the database can be output as various forms. |